Rubber transfer molding is an ideal process for molding parts that require multiple cavities intricate parts that require a closed mold bonding rubber to metal parts and if the geometry of the.

Rubber injection molding process pdf.

Based off of a process intended for the molding of plastics injection molding of rubber began in the mid 1960s.

Rubber injection molding successfully alters the plastics process by heating the rubber and placing it under significantly more pressure per square inch of cavity surface in molding.

In nature such as rubber cotton and silk.

Reduce the quality of the parts or even require a post molding curing process to cure completely.

Injection 5 injection too slow during the injection portion of the molding cycle the material does not fill the mold in the recommended injection time.

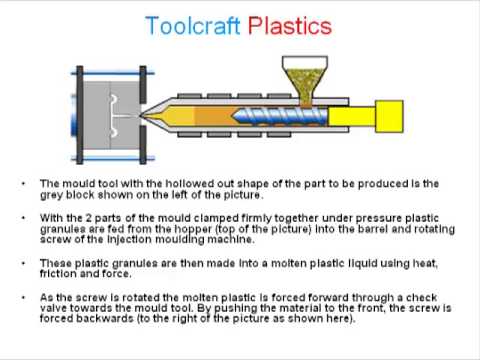

The injection machine is constructed of a mold clamping device that opens and closes the mold tool and.

The rubber injection molding process history.

Transfer molding combines the advantages of injection molding with the ease of compression molding.

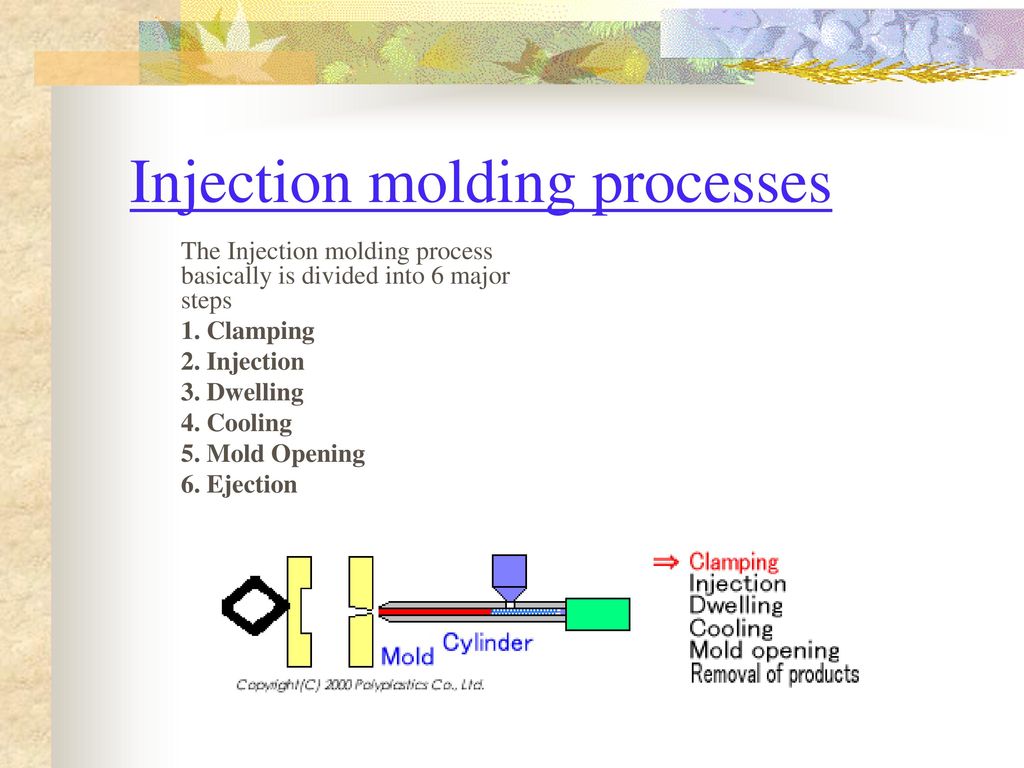

Injection molding 1 1 injection machine the injection machine is a machine that melt plasticize the molding material inside the heating cylinder and inject this into the mold tool to create the molded product by solidifying inside it.

During polymerization small molecules called monomers combine to form long polymer chains.

Rubber transfer molding.

Injection molding injection molding is the process in which the rubber material or compound is heated and while the material or compound is in a flowable state in the injection barrel the material or compound is forced or injected into the mold cavity.

Injection molding process and lifetime of a nr rubber part in dynamic application hans joachim graf injection molding conditions have an influence of lifetime of a part under dynamic load.

Injection molding calls for the use of man made synthetic polymers such as polyethylene abs and nylon.

Check injection throttle position and if possible increase its setting.

The key difference between plastic and rubber injection molding is that in rubber requires significantly higher pressure to cure the rubber thus leading to longer cure times.

Rubber injection molding was first used in the mid 1960s and was based on the plastic injection molding process.

7 3 3 2 injection moulding 136 7 3 4 configuration of injection moulding machines 137 7 3 5 the process requirements 137 7 3 5 1 debinding and sintering 137 7 4 a growing market for moulders 138 8 guide values and processing instructions for the most important thermoplastic injection moulding compounds 139 8 1 pre drying material 139.

As one can see injection molding elastomers is actually a very complex process.