Maximum economy in terms of price while maintaining and providing high quality reproduction long mould.

Rtv silicone mould making rubber instructions.

Work with a master mold.

It is easy to mix and de air and will.

Silicone rubber kits basic instructions.

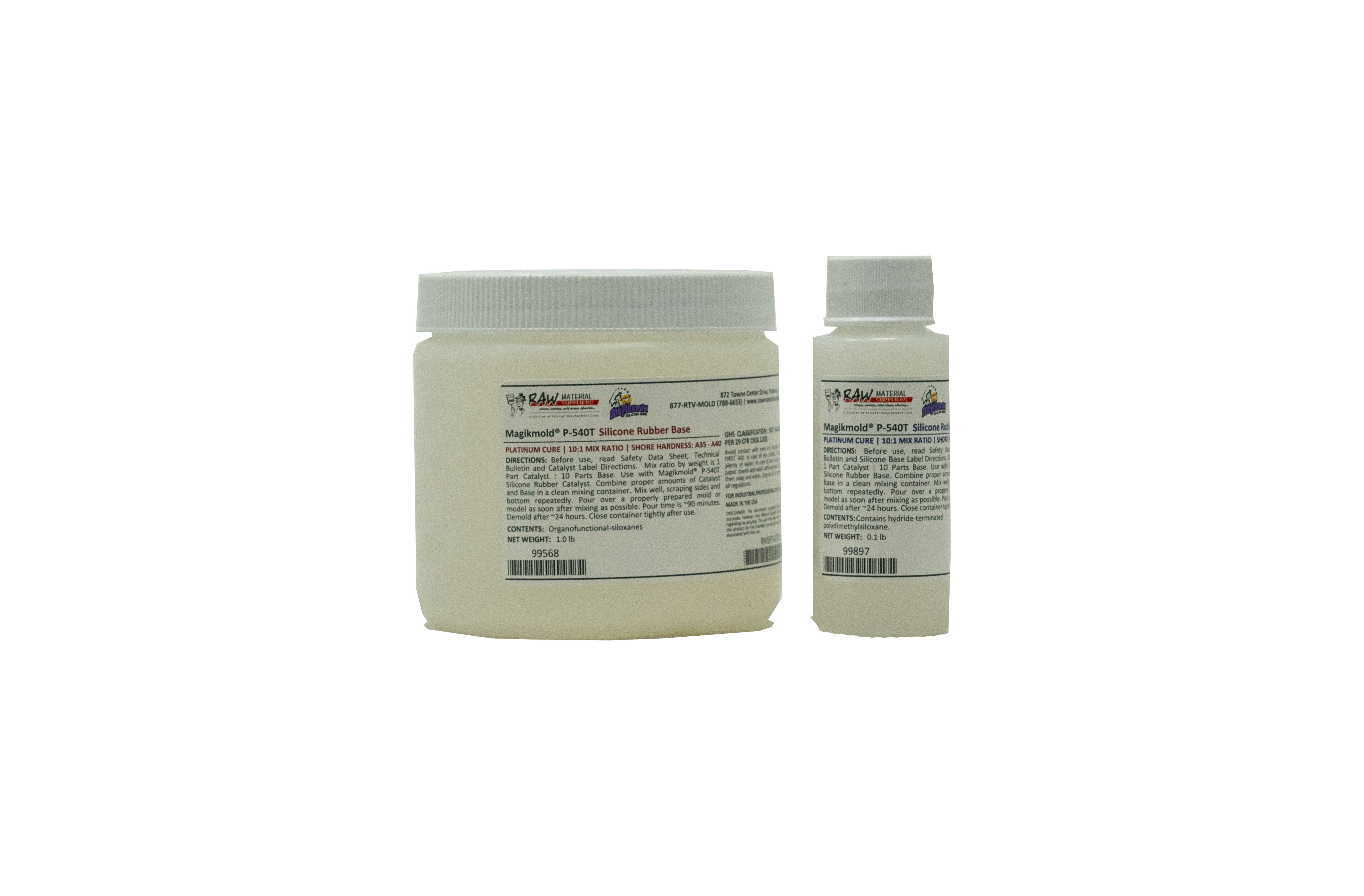

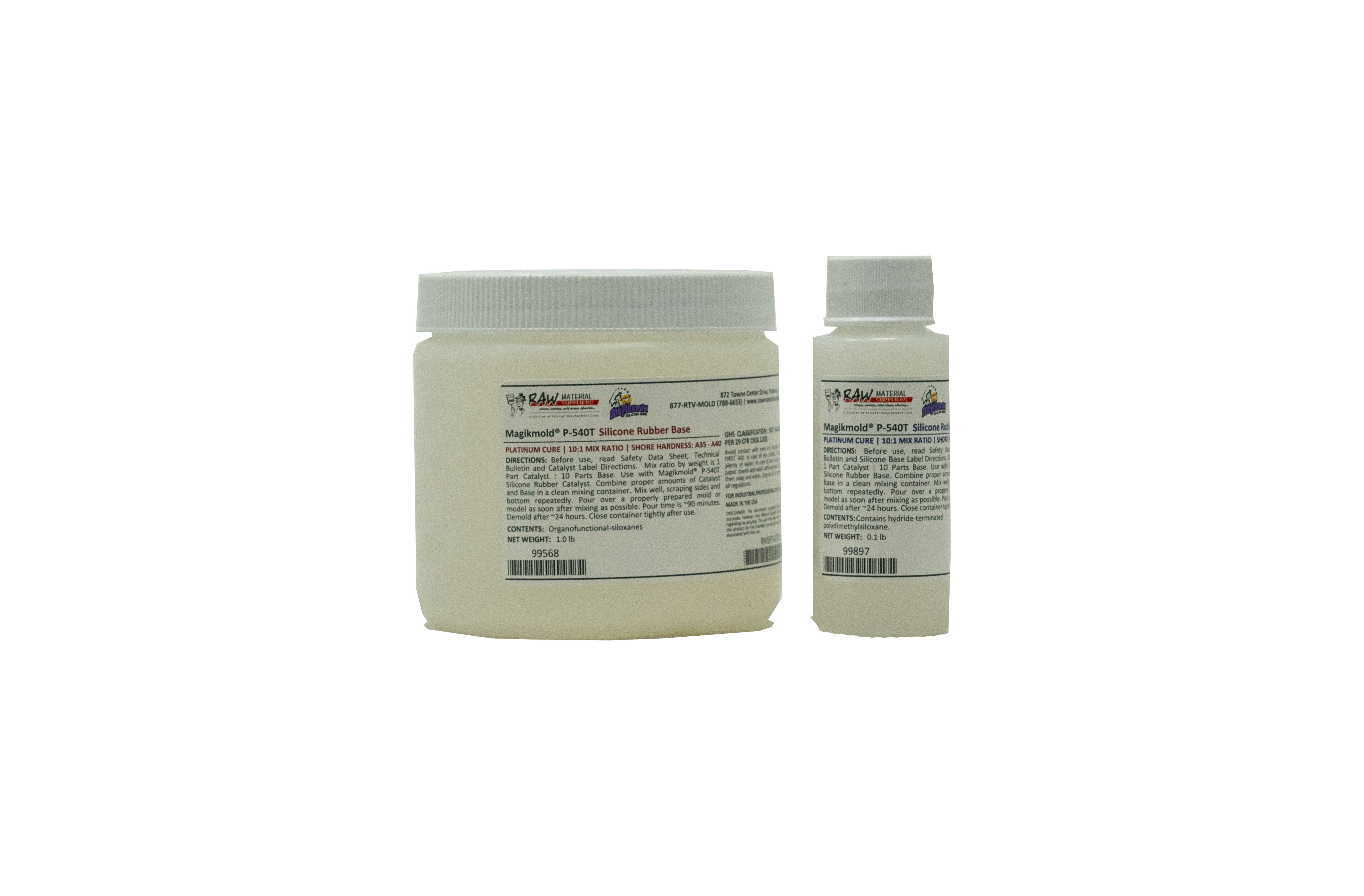

There is a part a and a part b that is mixed together at a 10 1 ratio applications.

It offers a number of benefits for the mold making process including excellent thermal resistance and long lasting flexibility.

The two components mix easily and because of the low viscosity most grades can be used without processing in a vacuum chamber.

High quality high strength tin cure rtv silicone polysol s rtv silicone mold making rubber is a two component material.

Which materials you need depends of course on your project and the type of mold production.

Making the silicone rubber mould is very simple and by following the mixing.

Liquid silicone rubber rtv room temperature vulcanizing is an easy and cost effective way to copy any piece ofjewellery by simply making a silicone rubber mould so a wax replica can be made and then using the lost wax system the new jewellery piece can be created in silver gold or other castable metals.

3 minutes due to its performance advantages and versatility rtv silicone rubber is becoming the preferred choice of many mold makers.

In addition to mold making silicone is widely used in other fields such as bonding sealing potting encapsulation.

Soft baits lures plastisol wax soap ultracal 30 epoxylow melt metals up to 400 degrees max polyester fiberglass resign plaster urethane rubber plastic hydrocal white mixing.

Other materials required for making your own silicone mold.

Our silicone has been formulated for easy mixing by hand with colour coded components red or green giving a visual aid to ensure mixing is adequate.

If you need to paint the silicone on our brushable silicone is a good option the general mold making am 128 rtv is sturdy and pourable and can be poured into a plastic or cardboard frame for convenient later use it s our most popular silicone rubber mold making kit.

Silicone molds making kit translucent liquid silicone rubber for mold making 1 1 mixing ratio fast curing molds making silicone for resin molds casting jewelry making diy crafts 21 16 oz 4 5 out of 5 stars 78.

Cast a mold 25t is a condensation cured silicone tin catalyzed it is used to make rubber molds that can be used to cast polyurethanes epoxy s polyester s cement concrete soap wax plaster etc.

To make such a silicone mold you generally need the following materials.

High strength silicone mould making rubber.

Silicone molds making kit translucent liquid silicone rubber for mold making 1 1 mixing ratio fast curing molds making silicone for resin molds casting jewelry making diy crafts 21 16 oz 4 7 out of 5 stars 27.

Life very low shrinkage and no risk of the sating material gripping the mould surface.

Silicone also comes in a number of different formats.